Advanced Composites for Long Lasting and Light-weight Building And Construction

Advanced Composites for Long Lasting and Light-weight Building And Construction

Blog Article

Exploring the Uses and Advantages of Recycled Composites in Modern Industries

In today's quickly developing industrial landscape, the application of recycled composites has actually gathered increasing interest for its possible to redefine traditional production methods. The combinations of recycled products with advanced composite modern technologies presents an encouraging method for boosting sustainability, durability, and cost-efficiency across numerous fields. As markets look for cutting-edge options to resolve ecological problems and improve operational effectiveness, the incorporation of recycled compounds becomes an engaging option. This change towards sustainable techniques not just straightens with global preservation initiatives but likewise offers a myriad of benefits that hold the secret to forming the future of modern production techniques.

Environmental Advantages of Recycled Compounds

The use of recycled composites in modern industries provides substantial ecological advantages, adding to the decrease of waste and the conservation of natural sources. By incorporating recycled compounds right into making procedures, sectors can lower their dependence on virgin materials, thereby decreasing the amount of waste generated and the energy required for removal and manufacturing. This change towards using recycled composites aids in diverting materials from landfills, minimizing the problem on waste administration systems, and lowering greenhouse gas exhausts connected with standard manufacturing techniques.

Furthermore, the use of recycled composites advertises the preservation of natural resources such as timber, minerals, and water, which are frequently depleted via the extraction and processing of basic materials (composites). By expanding the life-span of products with recycling, markets can help preserve environments and biodiversity by lowering the need for brand-new sources. On the whole, the fostering of recycled compounds in modern-day markets plays a vital function in advertising sustainability and reducing the environmental effect of manufacturing processes

Boosted Resilience in Product Production

With a focus on long life and robustness, incorporating recycled compounds right into product manufacturing procedures improves resilience and sustainability. By using recycled composites, makers can produce items that are not just strong but also immune to wear and tear, making them excellent for long-term usage in different sectors. The mix of different materials in recycled compounds can often result in improved stamina and toughness compared to conventional products, giving an economical service for generating durable items.

Among the key advantages of making use of recycled compounds in product production is the capability to customize the material residential or commercial properties to satisfy details resilience demands. By readjusting the make-up and manufacturing methods, makers can tailor the recycled compounds to withstand harsh ecological conditions, hefty loads, or regular use without compromising on performance. This adaptability in style and manufacturing permits for the production of very long lasting items that keep their integrity over time, minimizing the requirement for regular replacements and eventually contributing to a more sustainable manufacturing process.

Cost-Effectiveness and Economic Advantages

Incorporating recycled compounds right into product production not only enhances toughness and sustainability however likewise supplies significant cost-effectiveness and economic advantages. Using recycled compounds can cause decreased material expenses as recycled products are often more economical than virgin products. Additionally, reusing composite products can lower garbage disposal expenses and lower the need for landfill area, adding to total cost financial savings for industries.

Advancement and Layout Adaptability With Recycled Compounds

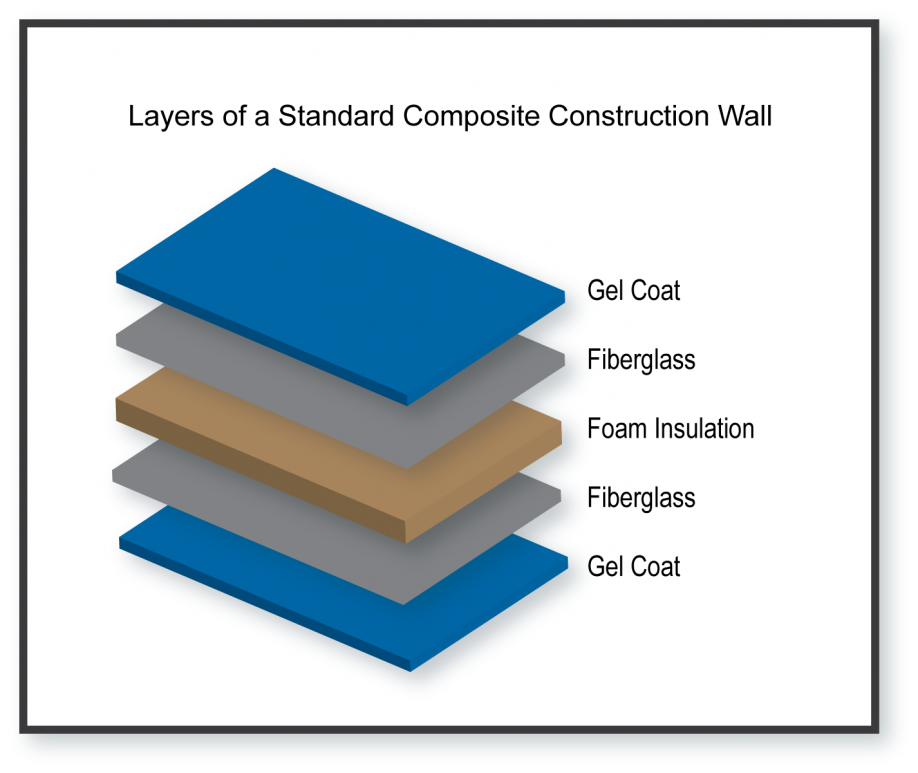

Making use of recycled compounds in modern-day industries uses unparalleled possibilities for innovation and layout flexibility. By incorporating recycled materials into composite manufacturing processes, companies can press the borders of typical layout restraints and discover brand-new opportunities. The versatility of recycled compounds permits the production of intricate forms and frameworks that might not be possible with conventional materials.

One of the key advantages of recycled composites is their ability to be molded right into various forms, offering developers the liberty to explore one-of-a-kind sizes and shapes. composites. This flexibility opens a globe of creative possibilities, enabling the advancement of lightweight yet durable products that satisfy the details needs of various industries

In addition, using recycled composites advertises sustainable techniques and supports the circular economic situation by minimizing waste and minimizing the environmental effect of making processes. This concentrate on green style solutions aligns with the expanding trend towards sustainability in modern-day industries, making recycled compounds a useful resource for cutting-edge and forward-thinking companies.

Applications Throughout Numerous Industries

Recycled composites locate diverse and impactful applications across a large variety of markets due to their unique residential or commercial properties and sustainability benefits. The aerospace industry advantages from recycled compounds in the production of airplane parts, where the products' strength-to-weight ratio is vital for guaranteeing safety and security and performance. The versatility and sustainability of recycled compounds make them important across numerous markets, driving innovation and environmental stewardship.

Conclusion

To conclude, the use of recycled composites in modern markets supplies significant ecological benefits, improved sturdiness in item manufacturing, cost-effectiveness, and financial advantages. The use of recycled discover this compounds permits for advancement and layout flexibility throughout different industries. Overall, the fostering of recycled composites offers a functional and sustainable solution for satisfying the needs of the sector while also lowering environmental influence.

One of the key benefits of utilizing recycled composites in item manufacturing is the capacity to customize the material buildings to satisfy specific sturdiness requirements. Using recycled composites can lead to decreased product prices as recycled materials are typically less costly than virgin materials. The aerospace market benefits from recycled compounds in the manufacturing of airplane components, where the materials' strength-to-weight proportion is critical for making sure safety and efficiency.

Report this page